Plastic & Rubber Moulds Hard Chrome Plating

Plastic & Rubber Moulds Hard Chrome Plating Specification

- Usage

- Industrial Moulds

- Surface Preparation

- Mechanical polishing before plating

- Wear Resistance

- Enhanced for long tool life

- Finish

- Mirror Finish, Hard Chrome

- Application

- Moulds for Plastic and Rubber Industries

- Adhesion Strength

- Excellent

- Features

- Corrosion Resistance, High Surface Hardness

- Hardness after Plating

- Up to 1000 HV

- Thickness of Plating

- Up to 60 Microns

- Plating Technology

- Electroplating

- Material

- Steel, Aluminium

- Coating Uniformity

- Highly Uniform

- Service Location

- On-site or Off-site

- Type

- Plastic & Rubber Moulds Hard Chrome Plating

- Temperature Resistance

- Up to 400°C

- Color

- Silver

About Plastic & Rubber Moulds Hard Chrome Plating

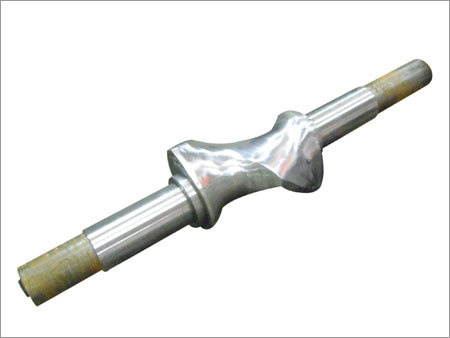

Hard Chrome Plating on Plastic & Rubber Moulds

Established in the year 1990, we, India Hardchrome is the leading company engaged in providing Hard Chrome Plating on Plastic & Rubber Moulds. We have with us highly skilled manpower, who render these plated services as per requirement of clients. These kinds of services are highly used in power press, injection molding machine, hydraulic press & many more. Our Hard Chrome Plating on Plastic & Rubber Moulds protect the surface of metals and to help it to remain abrasion resistant and extend wear life.

Advanced Electroplating for Industrial Moulds

Specializing in hard chrome plating for plastic and rubber moulds, we employ state-of-the-art electroplating technology to achieve highly uniform coatings with up to 1000 HV hardness. This technique guarantees enhanced surface durability, allowing moulds to perform reliably even in demanding production environments. Our process is tailored for steel and aluminium moulds to ensure compatibility and optimal performance.

Mirror Finish with Superior Resistance

Our hard chrome plating service delivers a brilliant mirror finish with significant resistance to wear, corrosion, and elevated temperatures up to 400C. The treated moulds showcase improved longevity and can withstand the challenging processes encountered in industrial plastic and rubber manufacturing. Each mould is mechanically polished before plating to enhance adhesion and produce an exceptional surface finish.

Flexible Service Delivery Across India

We provide both on-site and off-site chrome plating services anywhere in India, accommodating diverse operational needs. Whether your moulds require minimal downtime or can be treated off-site for convenience, our team ensures prompt, professional service. With coating thicknesses up to 60 microns and tailored solutions, we help maximize your tools productivity and lifespan.

FAQs of Plastic & Rubber Moulds Hard Chrome Plating:

Q: How does hard chrome plating benefit plastic and rubber moulds?

A: Hard chrome plating significantly enhances the surface hardness, wear resistance, and corrosion resistance of plastic and rubber moulds. This results in longer tool life, reduced maintenance costs, and improved mould efficiency during industrial production.Q: What is the process for hard chrome plating on moulds?

A: The process begins with thorough mechanical polishing of the mould surface to ensure proper adhesion. After preparation, hard chrome is applied using electroplating technology, producing a highly uniform, mirror-finish coating up to 60 microns thick with excellent hardness and protection.Q: When should I consider chrome plating for my moulds?

A: Chrome plating is recommended when your moulds begin to show signs of wear, surface corrosion, or decreased performance, or if you wish to extend the life and quality of new steel or aluminium moulds. It is especially valuable in high-volume or high-precision manufacturing environments.Q: Where are your hard chrome plating services available?

A: We offer both on-site and off-site hard chrome plating services throughout India. This flexible approach allows clients to choose the best logistics solution for their operations and scheduling needs.Q: What materials can be plated using your service?

A: Our hard chrome plating is suitable for industrial moulds made from steel or aluminium, commonly used in plastic and rubber manufacturing processes. The service delivers excellent adhesion and surface finish on both material types.Q: How is uniformity and adhesion ensured during plating?

A: We achieve highly uniform coatings and excellent adhesion through advanced electroplating techniques and meticulous mechanical polishing before plating. This preparation eliminates imperfections and optimizes the bond between chrome and substrate.Q: What are the main advantages of hard chrome plating for industrial use?

A: Key advantages include vastly improved wear resistance, superior surface hardness (up to 1000 HV), corrosion protection, high-temperature resistance (up to 400C), and a long-lasting, mirror-like finish. Together, these benefits result in reduced mould downtime and enhanced production performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry